Automotive

Lightweight construction with EPS Styrofoam® and EPP particle foam

Fully Protected

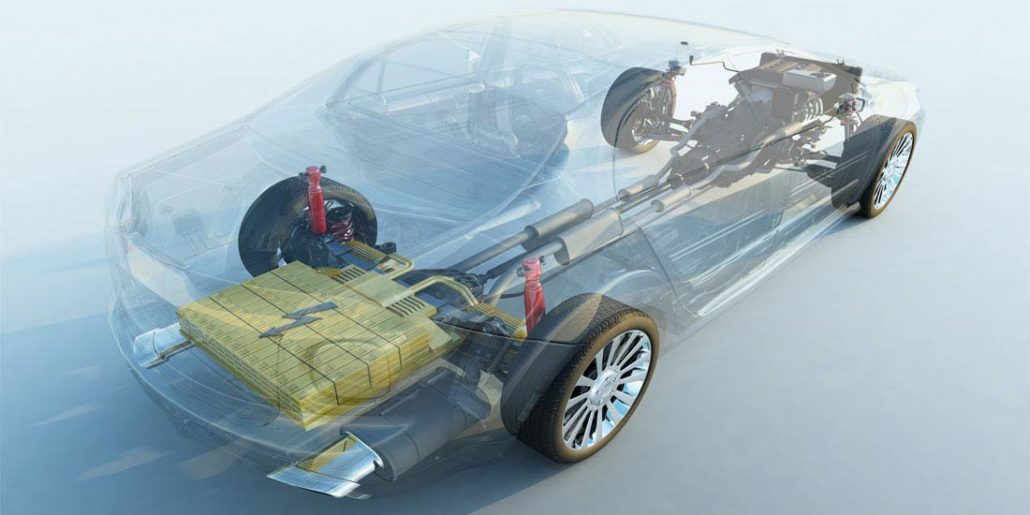

Due to their special properties, particle foams EPS Styrofoam® and EPP are ideally suited for a wide range of automotive applications. For example, inserts made of particle foam have an excellent ability to absorb energy under dynamic load. Impact absorbers in the floor, in headliners and side panels, in steering column, headrests and bumpers are used primarily for the passive protection of occupants and chassis. In the case of electric vehicles, the protection of battery systems should be emphasized.

Lightly Constructed

There is no doubt that the use of particle foam is trend-setting for the construction of vehicles / Caravans / Motorhomes. Interesting features are not only the great freedom of design, but also the high structural strength at very low weight, the good resilience and the functional safety within large temperature ranges. Lightweight construction is the trend, because reducing vehicle weight saves fuel and costs, increases the range of electric vehicles and thus contributes to the reduction of CO₂ emissions. The material is already being used in innovative rear seat designs, door panels, the trunk and wheel arches, among other things.

Well insulated

The construction of electric vehicles places new demands on vehicle insulation. Particle foam can also make a contribution here: in energy management through its excellent thermal insulation values, as well as its good sound absorption capacity. In addition to the use of particle foam as the core of composite materials, the material is also increasingly used in the visible area. Attractive surfaces through laser textures and colours play an important role here.

Advantages of the material

EPS (Styrofoam® | airpop®) and EPP are characterized above all by low weight and excellent energy absorption. EPP in particular can absorb a repeated impact very well. This does not cause any visible damage. These two particle foams have very good thermal insulation and optimized temperature resistance. EPP is resistant to water, most chemicals and oils and retains its structure in various applications with high loads. It also withstands temperatures from minus 25 to 130 degrees. EPS (Styrofoam® | airpop®) and EPP are 100% recyclable.

Why use particle foam in automobiles?

Particle foams have a wide range of positive properties, especially for the automotive sector / Caravans / Motorhomes, which no other material in combination can fulfil:

- High structural strength

- Extremely low weight

- High energy absorption

- High resilience with EPP

- 100% recyclable

- Good chemical resistance with EPP

- Good sound insulation/sound absorption

- Excellent thermal insulation, e.g. for e-mobility

- Great freedom of design

Lightweight construction in caravans with EPP

Schaumaplast is one of the leading processors of EPP and other particle foams such as EPS, E-TPU and Sun-Force. It has been developing and producing lightweight construction solutions for caravan and motorhome manufacturers for many years.

EPP combines lightweight construction with high rigidity and compressive strength, thus making an important contribution to weight reduction and energy efficiency.

At the same time, the material offers excellent thermal and acoustic insulation, high comfort and safety thanks to its outstanding impact resistance and resilience, while also being resistant to moisture and chemicals such as oils and greases.

Thanks to its great freedom of form and design, even complex geometries can be realised and the design, density and colour can be completely customised.

EPP construction material – lightweight and efficient

Schaumaplast stands for EPP expertise that makes vehicles, caravans and motorhomes lighter and more efficient:

- 3.5-tonne limit for Class B driving licence is maintained

- SAFETY PLUS Energy absorption and crash behaviour

- PREMIUM COMFORT Heat and sound insulation

- SUSTAINABLE EPP is 100% recyclable

- FASTER TO SERIES production mouldable, functionally integrated parts

- HYGIENE & DURABILITY moisture-resistant and stable

- OPERATING COST ADVANTAGES lower consumption

Sound insulation in automobiles

The increasing need for comfort when driving calls for innovative concepts in car body construction. Particle foam can make a significant positive contribution here. A special particle foam, p-EPP, is of particular interest for sound insulation in the automotive sector. Porous EPP has a unique cavity structure and can therefore absorb noise extremely well. Due to its porous surface, it can also be excellently foamed into e.g. carpets of the footwell.

Laser Textures – aesthetics and functionality with EPP

Laser structuring brings EPP components to a PREMIUM LEVEL, both visually and technically, for more functions and more individuality. The result is high-quality surfaces that blend perfectly into the design of the vehicle/motorhome/caravan and are also more robust in use.

- PREMIUM LOOK High-quality and modern visible surfaces.

- DESIGN FREEDOM From fine grain patterns, e.g. leather look, to graphic signature designs.

- HAPTIC Sensibly pleasant feel and high-quality impression.

- WATERPROOF SURFACE ZONE Through targeted laser structuring, EPP particles on the surface can be fused together to form a closed, waterproof layer.

- DURABILITY Permanently abrasion and wear resistant, without additional coatings. The function is permanently retained.

Automotive Trends

- Use as core of composite materials, e.g. body insulation for electric vehicles

- High-density crash protection elements (densities from 100 to 300 g/l) as efficient occupant/battery protection for new generations of small lightweight vehicles with low buffer zones