rEPS

(Recycling EPS)

What is recycled EPS?

rEPS is composed of up to 35% recycled material*, making a significant contribution to reducing the ecological footprint. The careful selection and integration of recycled elements demonstrate a commitment to providing sustainable material solutions.

* White EPS with 35% recycled content;

Gray EPS (Neopor®) with 30% recycled content.

Mechanical properties

The mechanical properties of rEPS are comparable to those of conventional EPS. This includes strength, compressive strength, flexural, and impact resistance. By preserving these properties, rEPS proves to be a reliable and robust material.

Environmental friendliness

The high recycling content reduces dependence on primary raw materials and contributes to resource conservation. Additionally, rEPS is 100% recyclable, promoting a closed-loop economy.

rEPS: with up to 35% recycled material and 100% recyclability

rEPS consists of up to 35% recycled material. By incorporating recycled material, the consumption of primary raw materials is reduced, thereby minimizing environmental impacts in the manufacturing process.

The high recycled content of rEPS plays a crucial role in reducing the CO₂ footprint. The reuse of existing material helps decrease the need for new resources, thus minimizing the ecological footprint in production. This contribution to CO₂ reduction is a significant step towards climate protection.

Promoting a closed-loop circular economy

rEPS is 100% recyclable, promoting the concept of a closed-loop economy where materials at the end of their life cycle are not treated as waste but rather as valuable resources for new products. This sustainable approach helps close the loop on materials and minimizes the reliance on finite resources.

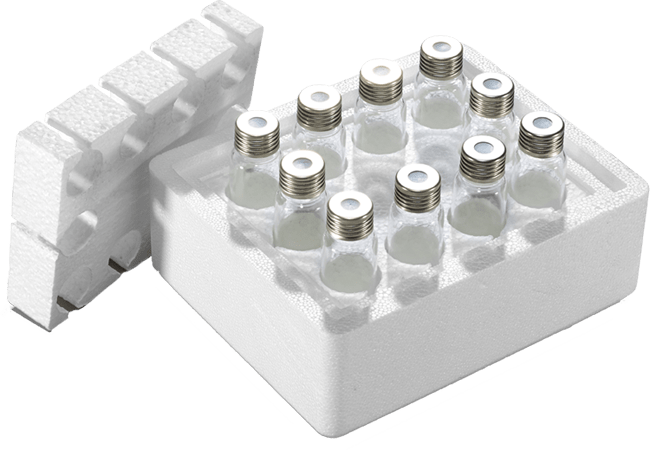

rEPS (recycled EPS) in packaging and polystyrene boxes

The shock-absorbing properties of rEPS make it an optimal material for protecting delicate goods during transportation. Whether delivering electronic devices, glassware, or other fragile products, rEPS prevents damage and ensures a secure arrival at the end consumer.

The thermal insulation of rEPS ensures that products requiring specific temperatures are optimally protected. This makes rEPS-based boxes particularly relevant for shipping food, medications, and other temperature-sensitive goods.

- Made from up to 35% recycled material*

- Lightweight

- Easy handling in logistics

- Customizable for shipping items

- Individual shapes & designs

- Identical properties to conventional EPS

- 100% recyclable

* White EPS with 35% recycled content; Gray EPS (Neopor®) with 30% recycled content.

rEPS (recycled EPS) in sports and leisure equipment

rEPS is characterized by its lightweight structure, making it an ideal material for the manufacturing of sports equipment. From helmets to shin guards, rEPS enables the construction of gear that is not only functional but also comfortably lightweight.

The high recycled content in rEPS underscores a commitment to sustainable practices in the production of sports and recreational equipment. The use of recycled materials contributes to resource conservation and promotes a more conscientious approach to limited resources.

rEPS is highly moldable, allowing for sophisticated design in the creation of sports equipment. This opens up creative possibilities for designers to develop innovative products that are not only thoughtfully functional but also aesthetically appealing.