EPS (Styrofoam | airpop®)

What is EPS?

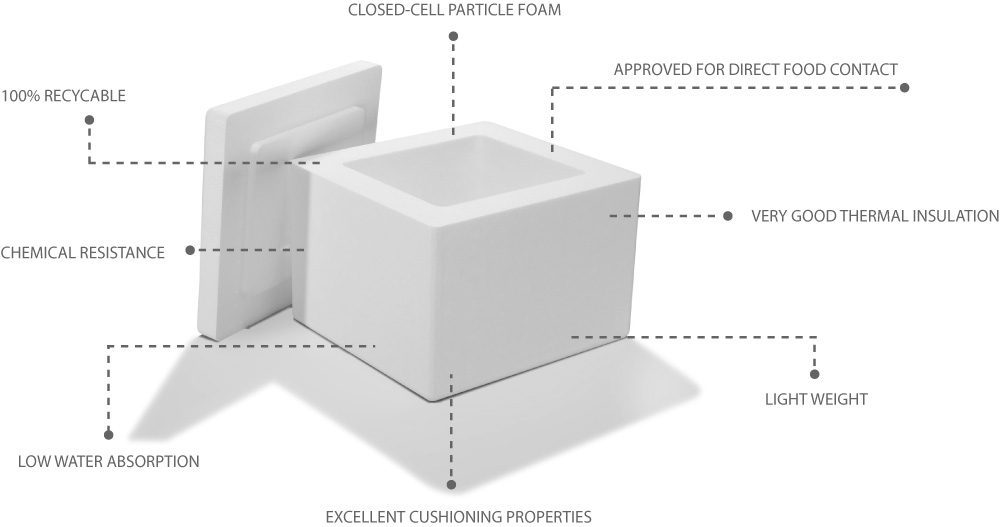

EPS is a polystyrene-based particle foam with unique properties. This versatile material not only protects your products during transport, but is also used in many technical applications.

Sustainability

EPS can be 100% recycled and is either directly returned to the production cycle or converted into polystyrene through melting processes to find a second life in new products.

Individual solutions

For each customer requirement we manufacture individually suitable solutions. Our transport packaging and blanks reliably protect your sensitive and high-quality goods. With our technical molded parts, a wide variety of geometries and applications can be realised. No matter whether EPS blanks, EPS boxes or EPS moldings, we have the know-how to realise your customer project quickly and reliably. Environmentally friendly and sustainable.

Advantages of the material

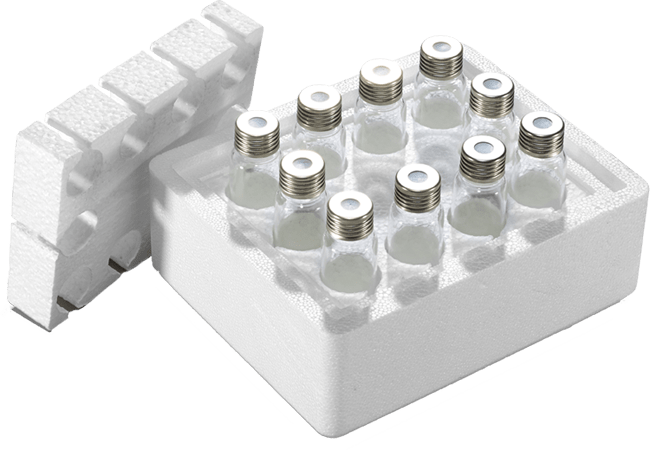

EPS Dunnage Trays

Dunnage trays made of EPS (Styrofoam® | airpop®) simplify logistics and thus reduce handling costs and the risk of breakage.

EPS Cistern

Cistern made of EPS (Styrofoam® | airpop®) for the HVAC industry.

EPS Airplane

EPS (Styrofoam) is an excellent particle foam for forming airplanes and drones. EPS is very light and yet robust.

EPS Balls

Balls made of EPS (Styrofoam®), ideal for handicrafts and decoration.

EPS Packaging

Perfectly fitting EPS packaging protects sensitive goods from breakage and damage due to its impact resistance.

EPS Packaging

In the illustrated EPS protective packaging, model cars are protected from transport damage.

EPS Moulded Part

Moulded parts made of EPS are very well suited for a lost foam process.

EPS Moulded Part

The Schaumaplast Group develops and produces your individual moulded part, adapted to your individual requirements.

Technical

Molded parts

Automotive

Packaging/

Transport

Construction industry

Sport/Leisure/

Design

Thermal Packaging

Cuttings

individual

customer solutions

Where can EPS be used?

EPS or also Styrofoam can be manufactured to almost any product and in any shape. Whether molded part, Styrofoam packaging or dunnage trays, but also as molded part for the automotive or construction industry – EPS is versatile. And its many positive properties, such as lightness and robustness, make the particle foam EPS a popular material.

EPS, airpop®, Styrofoam

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren