Special Foams

- Piocelan® / P-EPP -

What are Special Foams?

Particle foams are used for a variety of purposes. They also have to meet different important requirements. The different requirements require different properties of the particle foam used. Classical foams such as EPS (Styrofoam®) or EPP cannot always cover them 100%. For this purpose, special foams are used which have their strengths in different applications.

Special Foam Piocelan®

Thanks to new technology, the advantages of expandable polystyrene and polyolefin are combined into a unique, innovative material, Piocelan® foam. Piocelan®’s special structural characteristics guarantee that low density foams are possible. In addition, weight is reduced and low production costs conserve resources.

Individual solutions

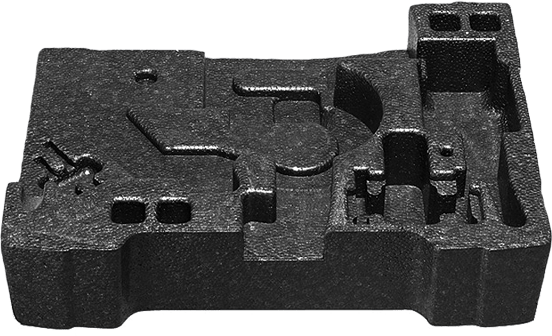

For every customer requirement we manufacture individually suitable solutions. Our transport packaging and hot wire cuttings reliably protect your sensitive and high-quality goods. Our technical molded parts can be used to create a wide variety of geometries and applications. Would you like to use Piocelan® for your products? Talk to us!

Piocelan®

Piocelan® is a versatile polystyrene foam. In a new, innovative process, conventional polystyrene and polyolefin are added, thus adding further properties. This combination allows Piocelan® to retain the characteristic advantages of polystyrene, such as high stiffness and low density, while improving shock absorption and flexibility. It also improves resistance to chemicals. Compared to EPS (expandable polystyrene), Piocelan® has significantly improved chemical resistance. Nowadays, Piocelan® is also processed into hard-wearing value-added packaging and robust molded parts. In addition to its improved chemical resistance, Piocelan® also stands out for its excellent mechanical properties and far surpasses materials such as EPS. The new material is ideally suited, for example, for the economical production of load carriers for electronics and precision components. The high flexibility of the material guarantees that we can realize almost any design according to customer requirements.

P-EPP

In contrast to conventional EPP, porous EPP impresses with particularly good sound insulation and is therefore preferred in the automotive industry for vehicle construction. Due to the characteristic structural cavities, P-EPP can improve acoustic comfort. The material is therefore frequently used for NHV suppression (noise, vibration, harshness). A further advantage of molded parts made of P-EPP is the improved adhesion to adhesives due to the hollow pearls, which is a desired side effect for the passenger compartment, especially when foamed into carpets.