Manufacturer of molded parts

from EPS, EPP and

other particle foams.

The Schaumaplast Group has been manufacturing molded parts and packaging from EPS, EPP, E-TPU (Infinergy) and other particle foams for various industries since 1964.

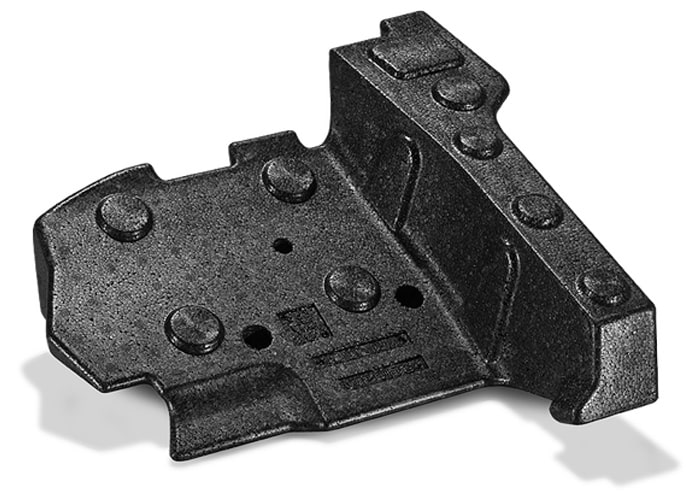

Automotive

HVAC

Sports/Leisure

Molded Parts

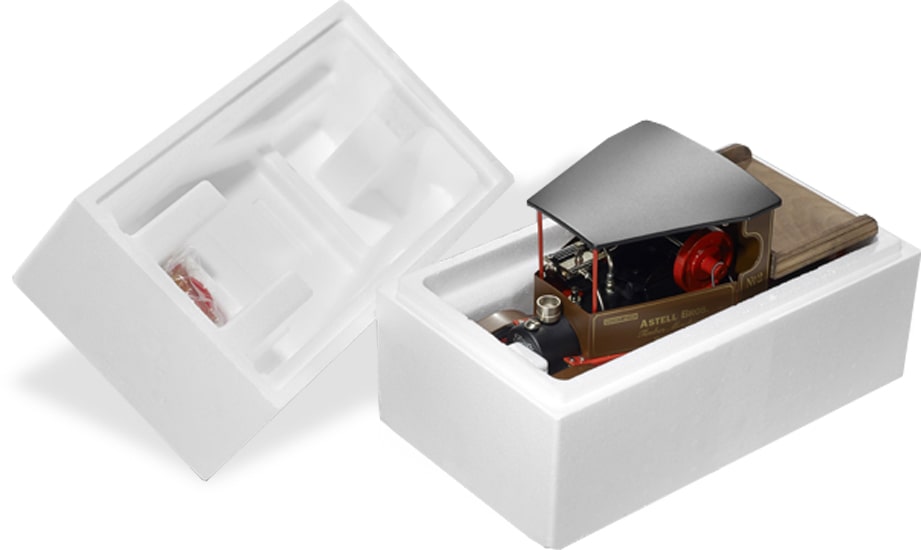

Packaging

Construction

Crafting/Binding

Cuttings

Cold Chain

Manufacturer for EPS molded parts,

EPP molded parts and others.

The Schaumaplast Group is an innovative manufacturer of moulded parts, contour cuts and packaging made of EPS (Styrofoam® | airpop®), EPP, eTPU and other particle foams. Schaumaplast produces particle foam products for companies in the automotive and construction industry, the pharmaceutical and biotech industry, but also in the sports and leisure industry.

THERMOCON, brand and business unit of the Schaumaplast Group, develops, produces and qualificates passive thermal packaging. The complete solutions, thermo boxes and cooling elements are used for the shipment of temperature-sensitive pharmaceutical and biotech products.

Known from

Our particle foam solutions

for your industry

Automotive

learn more

HVAC

learn more

Sports/Leisure

learn more

Molded Parts

learn more

Packaging/Load carrier

learn more

Construction industry

learn more

Cuttings

learn more

Cold Chain

learn more

Quality

Best quality is a central component of our company philosophy. Thinking ahead, rethinking and the zero-defect strategy are therefore the basic prerequisites for the quality management of the Schaumaplast Group.

Innovation

A continuous improvement process ensures that we work daily to improve customer satisfaction and adapt our processes and products to the ever-changing economic and ecological requirements.

Sustainable

EPS and polypropylene can be 100% recycled. Schaumaplast shreds particle foam residues in its own facilities and returns them to the production cycle.

Individual

There are hardly any limits to the refinement of your products. Be it antistatic finishing, dyeing, printing, painting, gluing or other assembly. Schaumaplast advises you on the possibilities of your individual customer solution.

Our Particle foams

EPS

learn more

Biomass Balance EPS

learn more

Grey EPS (Neopor®)

learn more

E-TPU (Infinergy®)

learn more

EPP

learn more

P-EPP

learn more

Piocelan®

learn more

Sunforce™

learn more