EPS (Styrofoam) Moldings

Versatile – across all industries.

What are EPS moldings?

The raw materials are foamed with the help of steam in molds to individual molded parts in various geometries and dimensions. EPS (Styrofoam® | airpop®), Neopor® or other particle foams can be used as raw materials. There are virtually no limits to the design and thus the variety of applications for particle foams as molded parts.

Wide range of applications

The performance of particle foams for different applications has become a matter of course. Transport boxes and packaging made of EPS (Styrofoam® | airpop®) ensure smooth transport while maintaining the cold chain. In the car, crash pads made of EPS (Styrofoam® | airpop®) protect the occupants safely from accidents, just like the bicycle helmet made of EPS (Styrofoam® | airpop®).

EPP moldings for your solution

Schaumaplast offers you the right EPP molded part, EPS molded part or molded parts made of other special foams for a wide range of applications. Each particle foam has its individual advantages and is selected according to the application and purpose of your molded part. The engineers of the Schaumaplast Group will inform you in detail about the numerous possibilities.

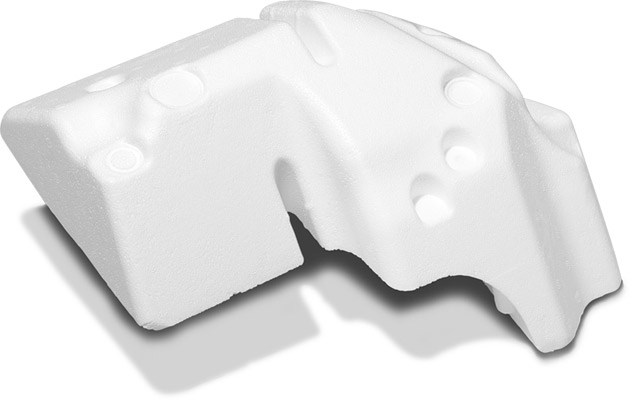

EPS molded part

Tube test tray made of EPS (Styrofoam) for safe and fast handling

EPS molded part

EPS glass pack to protect sensitive products from breakage during transport

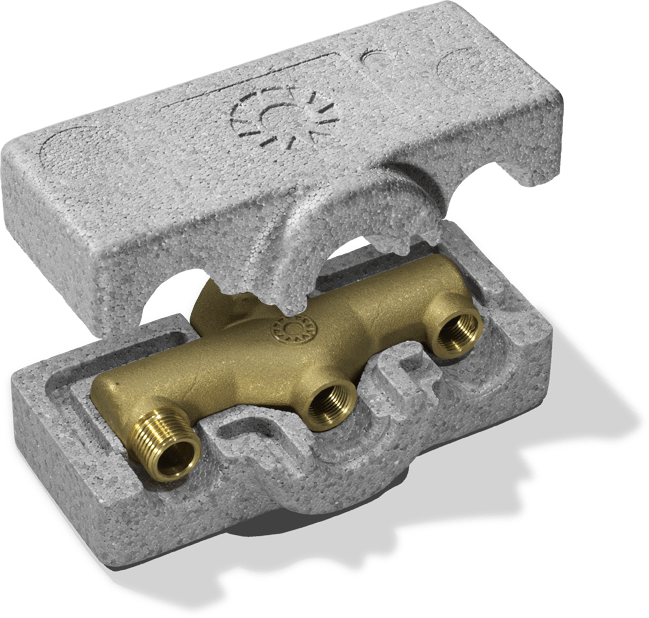

EPS molded part

EPS cold side manifold

EPS molded part

EPS (Styrofoam®) hot side manifold

EPS molded part

Individual Party Pack customer solution made of EPS

EPS molded part

EPS (Styrofoam®) shuttle sleeve

Neopor® molded part

Neopor® molded part as a tray for glasses. Simplifies handling, protects against breakage.

Neopor® molded part

Neopor® molded part as protective packaging for a lamp. Precise fit to the product.

EPS molded parts as packaging and trays

EPS molded parts as packaging and dunnage trays are used during transport to reliably protect sensitive and valuable goods. EPS has an excellent shock absorption. And can thus be used several times as packaging and dunnage trays. The dunnage trays also help to simplify and accelerate the handling of small parts between production stations.

EPS molded parts for the automotive industry

Motor vehicles are becoming heavier and heavier due to increasing electronics. Increased fuel consumption is the result. In order to counteract this development, materials with a low weight are needed while maintaining the same performance. In the automotive industry, EPS or EPP molded parts are used as foot or headrests, trunk floors, crash pads, inserts and other functional parts.

Particle foams play an important role in e-mobility and electric cars in particular. The weight of the vehicle is a significant criterion for the range of a battery charge. The lighter the electric car, the more efficiently the available energy can be used. EPS molded parts are also used here as battery insulation.

Individual molded parts made of EPS

Thanks to our many years of experience, we are also able to manufacture challenging individual solutions from particle foam. You can obtain everything from us from a single source – we prepare a technical design, advise you on the choice of the appropriate particle foam and produce the end product according to your requirements. We realize your project quickly and precisely. Transparency and communication at eye level is very important to us.

Neopor® shaped parts as insulation

Neopor molded parts are suitable where increased thermal insulation is to be achieved. The added graphite gives the classic EPS (Styrofoam) its grey colour and develops a high insulating performance. Due to its excellent thermal properties, the particle foam has also established itself in the construction industry and in heating and air conditioning technology. Neopor molded parts are used here as pipe insulation, as insulation for cisterns or fittings. The possible fields of application are extensive – we would be pleased to inform you about individual customer solutions using Neopor molded parts.

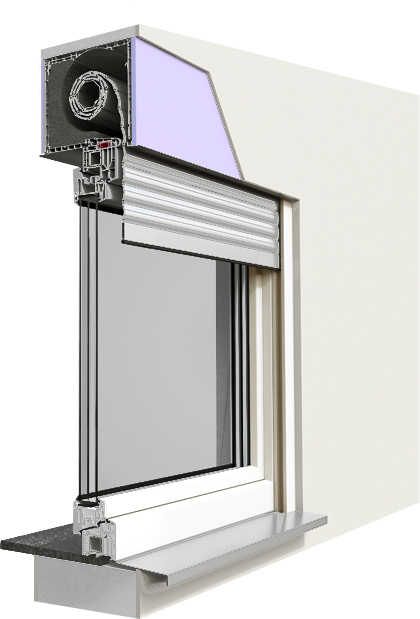

Neopor® moldings for the construction industry

EPS (Styrofoam® | airpop®) and Neopor® are processed into insulating elements for various parts of the building. The various areas of application include solutions for walls, roofs, panels for installing underfloor heating and perimeter floor troughs. Molded parts are also used as formwork elements and enable lightweight construction. Thermal insulation made of expandable foams helps to save up to 70 % of heating energy. EPS and Neopor® molded parts contribute to improved energy efficiency when used as roller shutter boxes.

EPP packaging and EPP trays

EPP molded parts as packaging and EPP dunnage trays are used during transport to reliably protect sensitive and valuable goods. Especially EPP has an excellent shock resistance and resilience. And can thus be used several times as packaging and dunnage trays.

ETPU / Infinergy® moldings

ETPU with BASF’s brand name Infinergy®, is an innovative high-performance particle foam. Infinergy® molded parts have properties such as extremely high damping and strong resilience. eTPU molded parts used as tires, wheels, saddles or as inserts in the sole of shoes can absorb hard shocks, thus protecting the joints and spine. Due to the high resilience, the material does not fatigue. The material has become well known in soles of sports shoes and running shoes and has now also established itself as an innovative and efficient material in many other applications.