Construction Industry ICF Styrofoam®

Energy efficiency with particle foams.

ICF EPS/Styrofoam

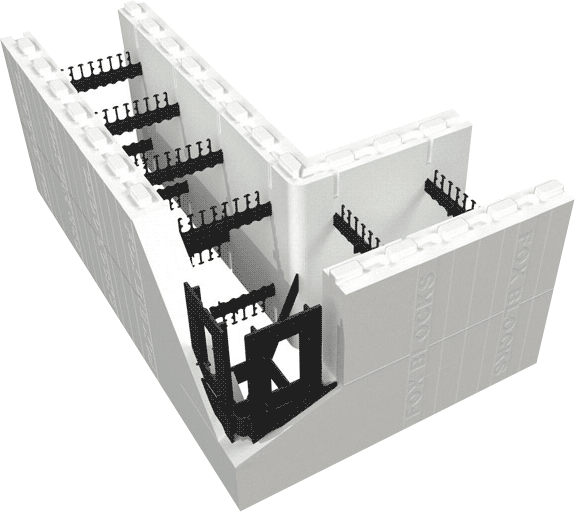

Styrofoam® ICFs are characterised by their modular and easy handling. They can be placed directly on top of each other like Lego blocks. Particle foams such as Styrofoam® (EPS | airpop®) and Neopor® have established themselves in the construction industry as reliable insulating elements. Whether insulation, thermal insulation or functional part, expandable particle foams are a material with a promising future. Styrofoam® ICFs contribute to considerable energy savings when used in house building or pool construction.

Areas of application

The areas of application are very diverse and include various solutions for walls and roofs, perimeter panels and panels for the installation of underfloor heating. In addition, ICFs are used to improve energy efficiency in house building. Besides high-quality packaging for a safe transport of your goods, Schaumaplast also produces various molded parts for the construction industry.

Spiral anchor

The spiral anchor for concrete construction is manufactured in a special concrete casting process. This is a new innovative holder for D15 tie rods. In this patented process, a spring made of 4mm steel with a Styrofoam® core is pressed into the fresh concrete or can be glued in during subsequent installation. As soon as the adhesive or concrete has hardened, all you need is a drill with a cordless screwdriver to remove the Styrofoam®.

ICF EPS/Styrofoam

Energy efficiency requirements for new buildings have been regulated by law for several years. Styrofoam ICFs simplify the fulfilment of these requirements: the erection of the walls and the insulation can be done in one operation. Styrofoam ICFs can be placed on top of each other like LEGO bricks. No mortar, no bricklaying and no crane is necessary.

- Easy handling – low weight

- Fast construction progress

- Solid construction

- Highest thermal insulation

- High heating cost savings

- Pollutant-free & 100% recyclable

- Pipes/cables are laid in the 5 cm thick inner insulation layer

- Sewage pipes can be installed directly into the wall and set in concrete

We would be happy to realise your ICF as part of a project. We do not offer ICF as a standard product.

Roller shutter box insulation

Modern house building would be unthinkable without facade insulation made of Styrofoam® or Neopor®. In addition to the popular facade panels, sophisticated technical moldings are also used. An interesting example of this is the insulation in the roller shutter box. Tanext® from the Alulux company is a particularly energy-saving roller shutter system for flush mounting in new buildings. Here, comprehensive insulation with the particle foam Neopor® prevents any formation of cavities and thermal bridges.

Neopor® particle foam is basically made of expanded polystyrene (EPS). The addition of graphite gives it its grey colour and further enhances its already good insulating properties. In this way heating costs can be saved.

Moldings for sanitary and heating

Molded parts made of EPS (Styrofoam®), Neopor® or EPP are also successfully used in the sanitary sector as well as in heating, ventilation and air-conditioning. Here they are used for example as pipe insulation, cistern insulation or ball valve insulation. Styrofoam® moldings are the most economical, Neopor® the most heat-efficient and EPP the most robust solution.