EPS Packaging & Trays

Particle Foam for Logistics and Transport.

EPS Trays

Today, EPS dunnage trays are an important part of the logistics chain for the transport of products between the individual production steps or as reusable means of transport in intralogistics. EPS dunnage trays from Schaumaplast meet all requirements set by customers from a wide range of industries through maximum dimensional accuracy. EPS dunnage trays are robust, shock-resistant and can therefore be used for many production cycles. They simplify handling, reduce breakage and increase efficiency at the production stations.

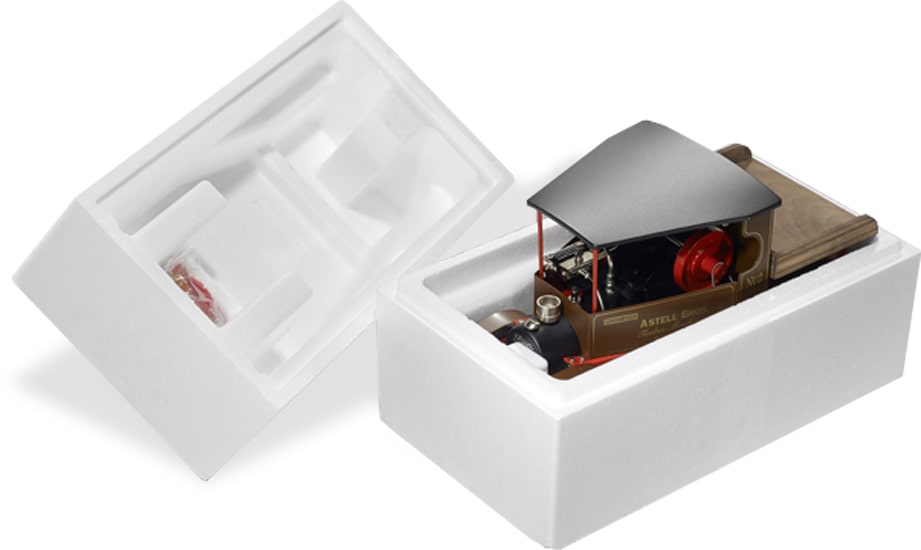

EPS Packaging

The Schaumaplast Group develops customer-specific EPS packaging and molded parts for sensitive and high-quality goods such as protective packaging for solar collectors, inverters or other electronic products. But Schaumaplast also offers a wide range of thermal packaging made of EPS (Styrofoam®) or EPP for reusable applications for temperature-sensitive goods under its own brand THERMOCON. The EPP and EPS packaging can be manufactured individually and precisely tailored to the respective goods to be transported.

Standard Program

Did you know that Schaumaplast supplies a comprehensive range of immediately available thermo boxes and protective corners for your safe transport? When choosing from our standard delivery program, there are no tooling costs for the customer for the production of the particle foam products.

EPS Packaging

Schaumaplast manufactures customized EPS packaging, which is characterized by its resistance and light weight. Tailor-made packaging is indispensable, especially for high-quality and sensitive products, in order to avoid transport damage under the extreme stresses of international shipping.

If the products are sensitive electronic components or plastic parts that can be painted afterwards, we also offer EPS packaging with ESD protection as an option. Due to this additional treatment, you benefit from permanent safety.

EPS Dunnage Trays

EPS dunnage trays are a good way to increase efficiency in the production of small parts and serial production. They serve as workpiece carriers and transport trays between the production stations or between manufacturer and processor. The EPS dunnage trays protect the parts from damage and breakage, they also simplify the handling of the individual parts.